Environmental Sustainability

Emerson helps customers across some of the world’s most essential industries make measurable sustainability progress, and we stand poised to help others along the same journey.

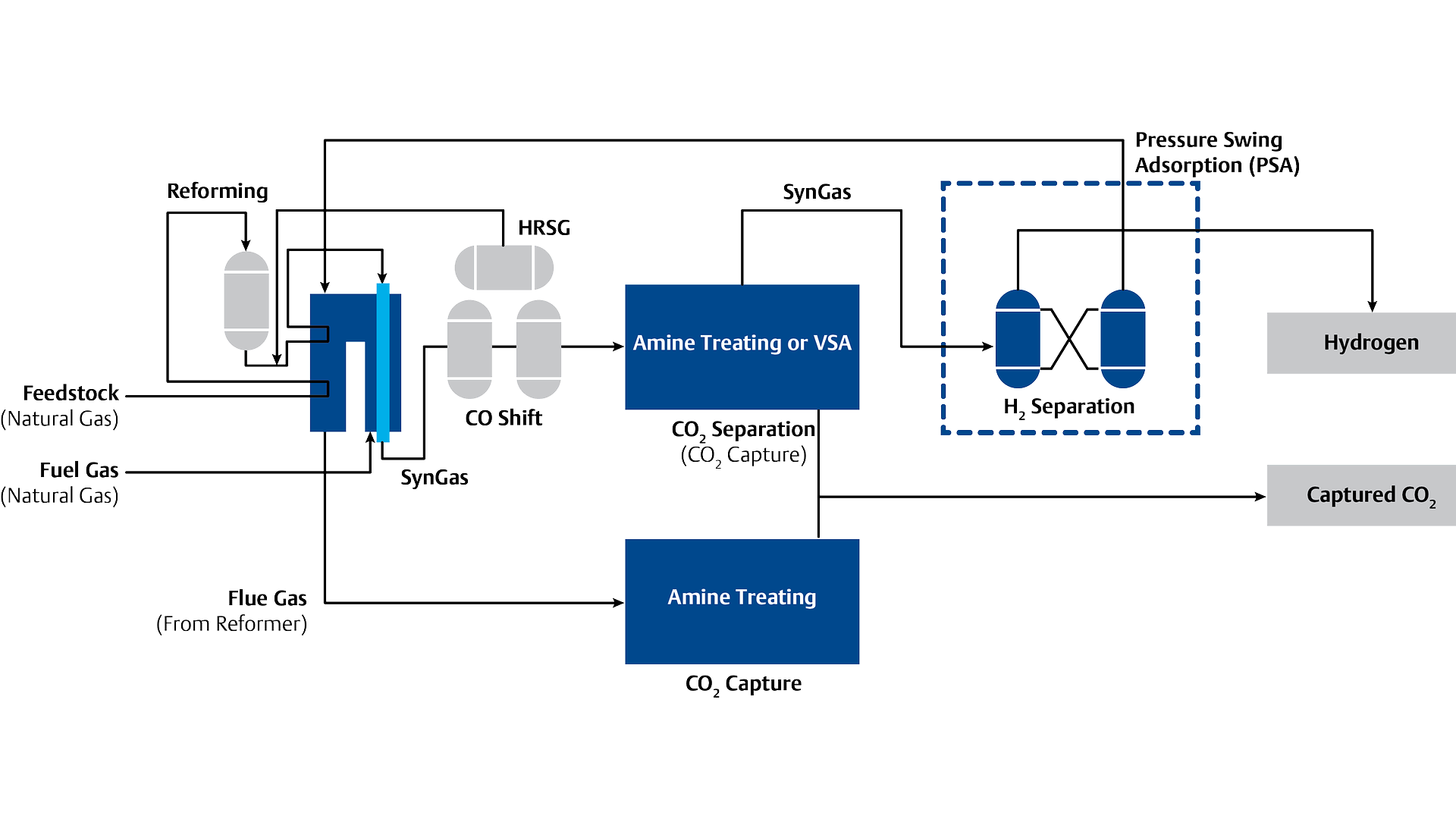

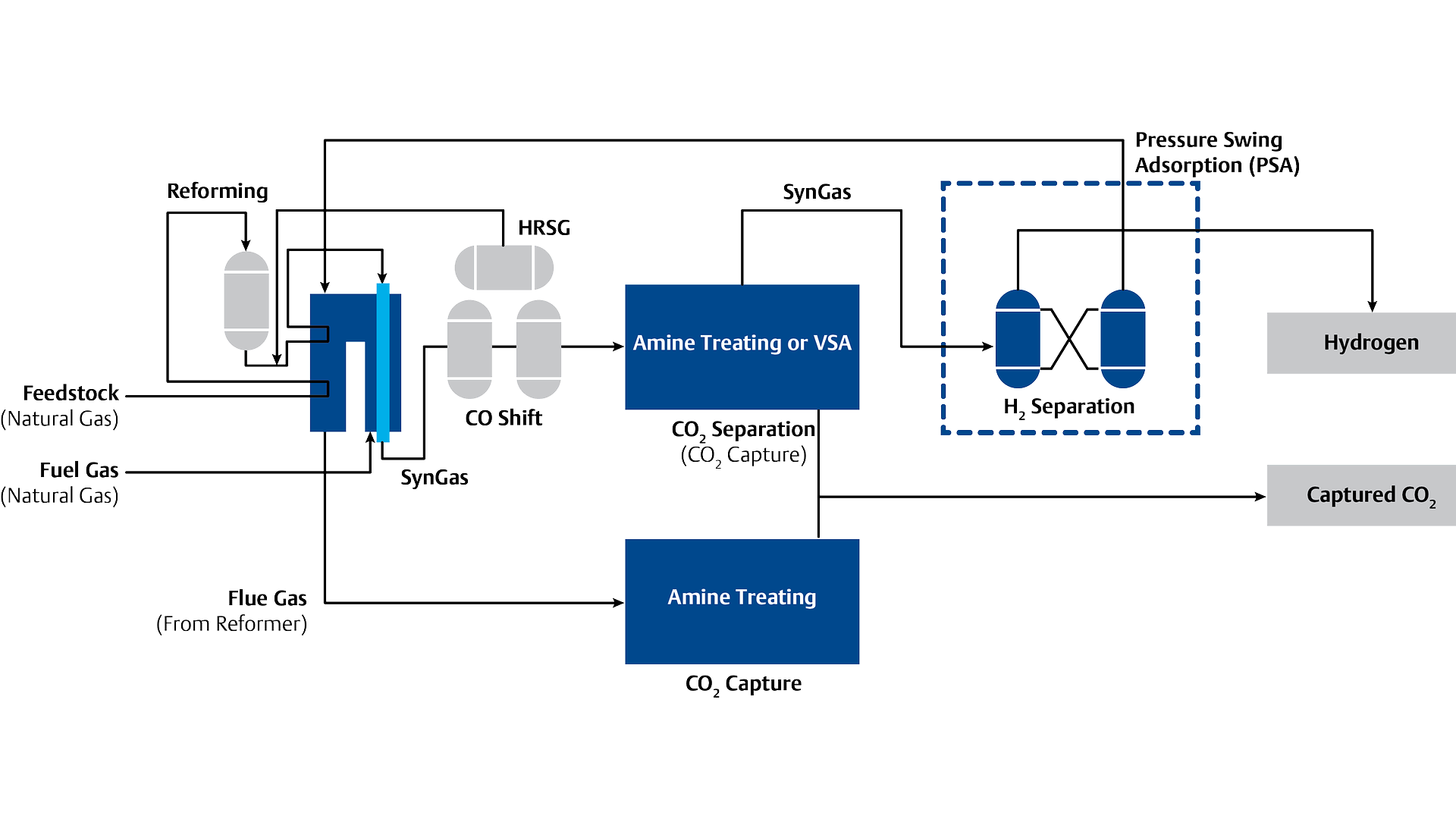

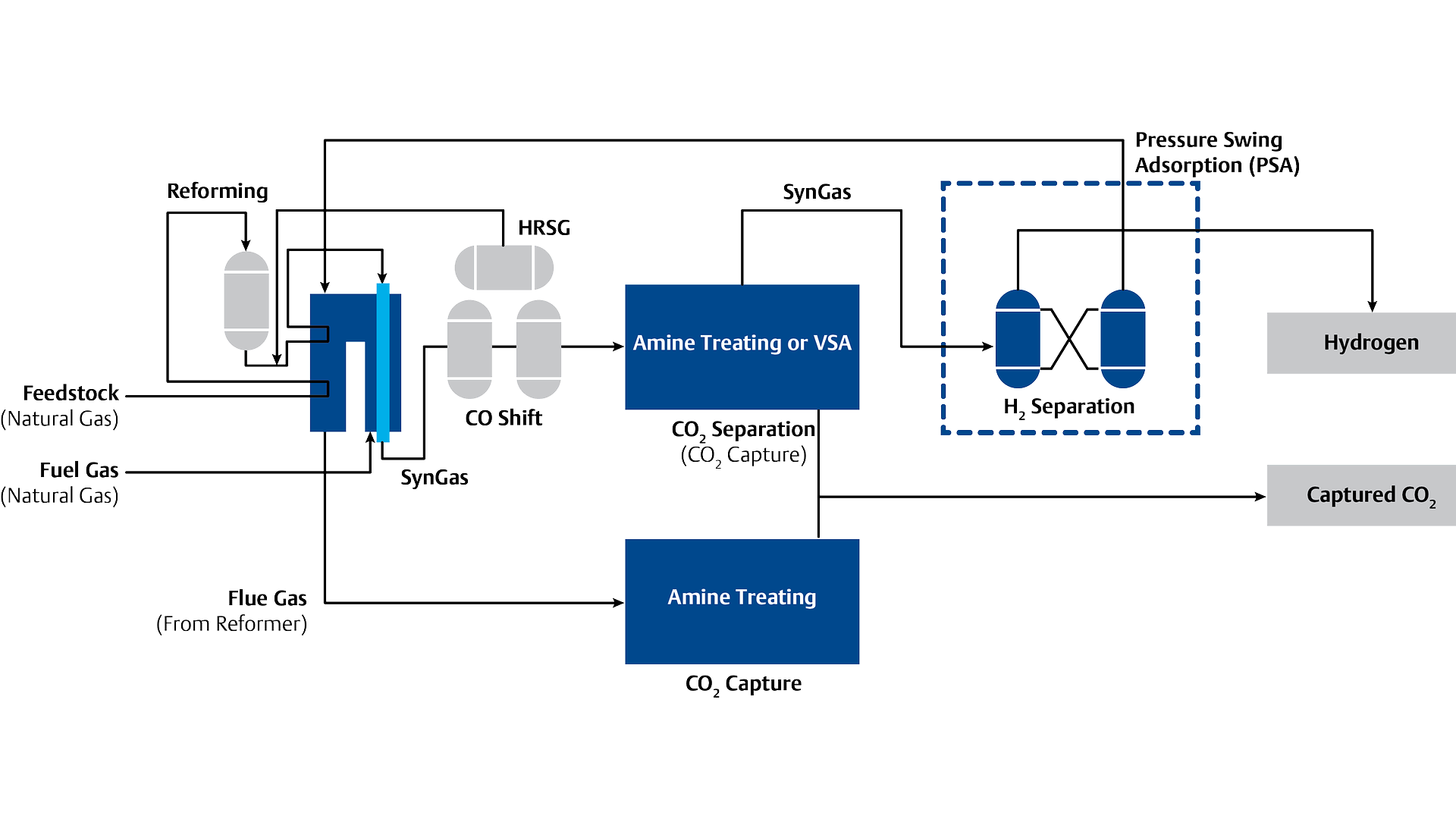

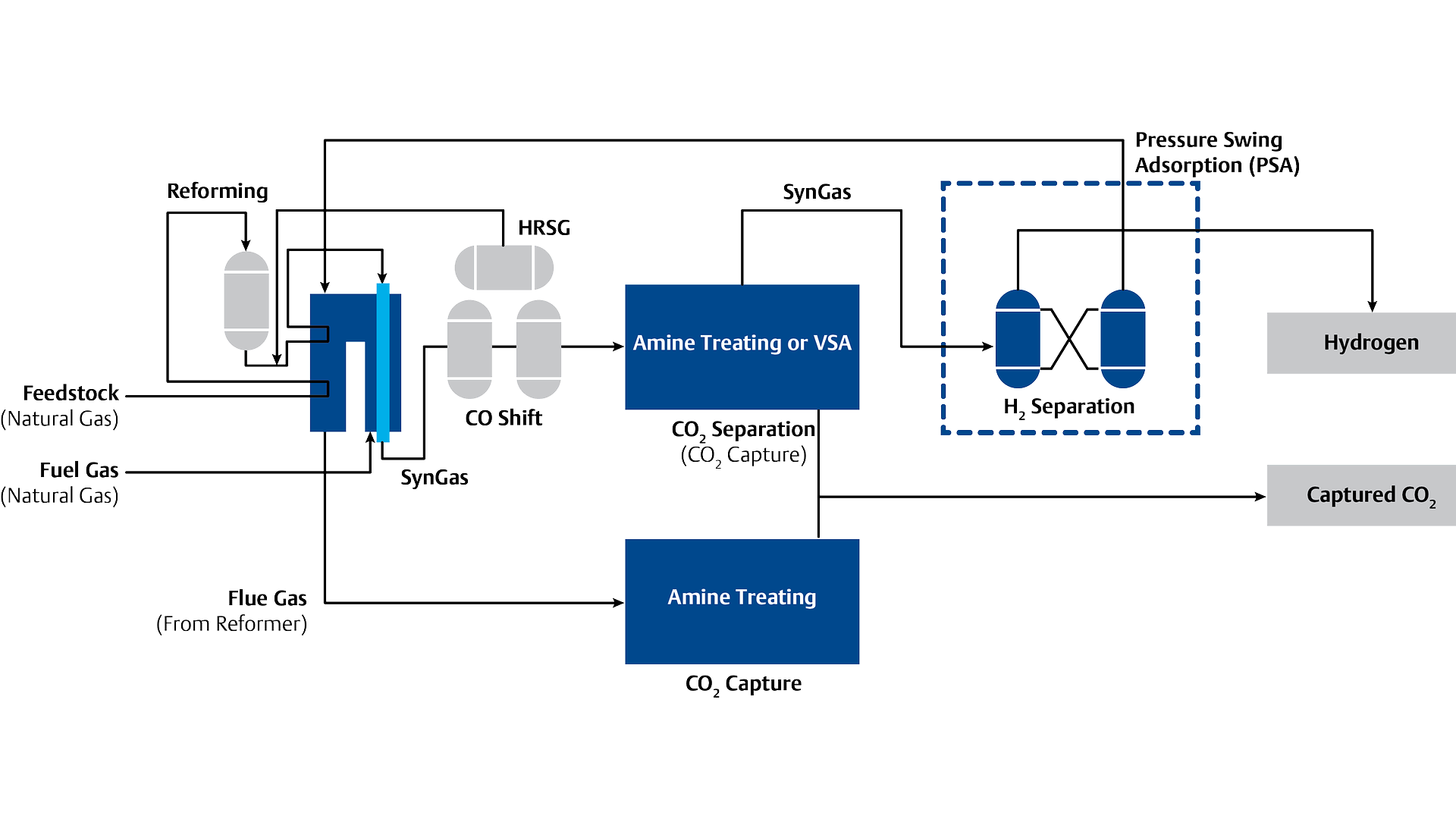

Natural gas reforming uses an advanced and mature process that builds upon the existing natural gas availability and infrastructure. In the United States, 95% of the hydrogen produced utilizes natural gas reforming* to enable and meet the demand for hydrogen production. Emerson supports operators through advanced technologies in steam methane reformer, amine treatment and vacuum swing adsorption.

ELITE Coriolis Meter

ELITE Coriolis flow meters are designed to deliver accurate, repeatable flow measurement for even the most challenging environments and applications

Rosemount Chromatograph and X-Stream Process Gas Analyzer

Precision analysis of multi-components in process applications down to ultra low ppm.

Equipment Performance Monitoring

Get easy and cost-effective access to your equipment performance data through our Performance and Condition Monitoring Service.

Anderson Greenwood Type 400 and 800 Safety Valves

Premium performance and advanced technology for overpressure protection

RX3i PLC (additional integration to DeltaV via MTP)

Emerson-supported MTP integration enables more modular manufacturing, reduces capital and operating costs, and accelerates digital transformation deployment.

Mimic Simulation Software

Mimic™ Simulation Software provides accurate and real-time simulation of plant behaviors.

Operators using amine treatment to capture carbon face a trade-off between capture efficiency and energy cost to regenerate solvent. Emerson supports operators through advanced technologies to reach peak efficiency.

DeltaV PK Controller with DeltaV PredictPro and Advanced Process Control

The most powerful and versatile DeltaV™ controller ever developed.

Anderson Greenwood Type 400 and 800 Safety Valves

Premium performance and advanced technology for overpressure protection

Micro Motion Compact Density Meter

The CDM provides precision density and temperature for custody transfer and concentration measurement.

Rosemount Permasence Ultrasonic Sensors

Permasense non-intrusive systems use sensor technology and wireless data delivery to continuously monitor for metal loss.

Fugitive Emission Ball Valve

With limited capital, addressing the thousands of potential leak paths in your plant can seem like a daunting challenge.

Pressure swing adsorption (PSA) cyclical process requires high levels of hydrogen purity to remove carbon dioxide from continuous gas streams. Using control and rotary valves along with gas analyzers, Emerson technologies ensure units operate reliably in critical high cycle operations.

Rosemount CT580 Gas Analyzer

Instantly detect and analyse gas molecules in the near and mid-infrared range with pin-point accuracy and repeatability.

KTM Metal Seated Valve

The world’s first supplier of full-bore, split-body ball valves and pioneered soft- and metal-seated valves.

Fisher™ FIELDVUE™ DVC6200 Digital Valve Controller

The DVC6200 allows for your operation to run closer to setpoint, improving product quality with more accurate control.

Fisher High Performance Butterfly Valve and Control Valve and Actuator System

Keep pressure swing adsorption (PSA) units operating reliably without unplanned interruptions.

Vacuum swing adsorption (VSA), an adsorption technique for post-combustion CO2 capture at atmospheric pressure, can achieve sequestration rates above 90%. High stroking frequency and stringent leak requirements make valve selection critical to minimize safety risks and avoid loss of containment.

Fisher High-Cycling Control Valves

Keep pressure swing adsorption (PSA) units operating reliably without unplanned interruptions.

Rosemount Gas Analyzers

Instantly detect and analyse gas molecules in the near and mid-infrared range with pin-point accuracy and repeatability.

KTM Metal Seated Valve

The world’s first supplier of full-bore, split-body ball valves and pioneered soft- and metal-seated valves.

BIFFI Quick-Acting Solutions

A dedicated pneumatic control panel grants the capability to fast closing and avoids chattering problems.

Fully leverage engineering expertise and solutions across the hydrogen value chain.

Emerson’s advantage lies in our innovative technological capabilities. In emerging markets, such as hydrogen adoption and production, modern technologies can be the difference between short-term and long-term success.

Emerson’s deep, global expertise in technologies and services can help any industry take on the tough challenge of adopting hydrogen at scale while reducing risk.

Emerson has solutions across the entire hydrogen value chain, giving our customers the competitive edge of working with a partner with deep domain expertise to address a variety of application challenges.

Frequently Asked Questions about Decarbonized Hydrogen

The term blue hydrogen refers to hydrogen produced from natural gas or coal using steam methane reforming (SMR) or other methods and separated from CO2, which is sequestered using carbon capture, utilization and storage (CCUS) reducing the levels of greenhouse gas emitted into the environment. The blue color denotes the far cleaner energy stream that results, which today is for the most part less costly and more commercially viable than fully renewable green hydrogen.

Blue hydrogen is not only several orders of magnitude less carbon intensive than gray hydrogen, which is produced from fossil fuels without CCUS, but the processes used are more easily scaled and well-tested than those available to make renewable hydrogen from electrolysis. These factors and the abundance of raw hydrocarbon feedstock could give blue hydrogen a cost advantage in the market as companies and consumers, particularly in transportation and heavy industry, weigh uncertainty in near-term energy prices against long-term sustainability goals.

Existing fossil fuel-based hydrogen generation methods and CCUS all require energy, capital resources and workforces to operate, and there will likely always be industrial processes that emit some positive net level of carbon. The primary concerns for blue hydrogen producers and users today are safety, efficiency and reliability. Ensuring purity, precisely controlling process units, achieving the highest possible CO2 capture rates, optimizing storage capacity, and managing energy and maintenance costs are all necessary to make sure a steady supply of hydrogen is available to meet quickly rising demand.

The most common method of manufacturing hydrogen from natural gas, steam methane reforming, is integral to the industrial-scale commercial production of blue hydrogen. SMR applies steam under tremendous temperature and pressure to a chemical catalyst that separates hydrogen from feedstock and binds carbon to oxygen atoms from water, forming CO2 as a byproduct. The throughput and efficiency of the process depends on maintaining an optimal ratio of steam to carbon entering the reformer, protecting the catalyst from coking and managing energy usage.

CCUS refers to various greenhouse emissions reduction technologies applied to the energy value chain. In the case of blue hydrogen, three of the most used and well-understood methods of carbon capture are vacuum swing adsorption (VSA) and pressure swing adsorption (PSA), both of which are capable of capture rates above 90%, and amine-based adsorption. The challenges involving PSA and VSA are similar – ensuring safety, purity and reliability despite very high cycle rates and preventing leaks that cause lower capture efficiency. Amine-based adsorption involves a tradeoff between the energy needed to regenerate the chemical solvent used in the carbon capture process and the rate of efficiency of the process itself.

A key selling point for decarbonized (blue) hydrogen is that the kinds of automation technologies needed to drive costs down and keep efficiency up already exist and are relatively inexpensive. Automation can improve the efficiency and profitability of SMR units by controlling the steam-to-carbon ratio with greater precision using advanced process control systems, online asset monitoring and mass flow meters. It’s possible to extend the life of the catalyst using continuous chemical composition analysis, which is essential for improving the performance of the above-mentioned CCUS methods as well. When applied to evaluate energy-related KPIs, energy management information systems (EMIS) make it easier for hydrogen plants to hit their operations’ optimal steam and electricity usage targets

There is no single path to decarbonization, and the familiar phrase “energy transition” recognizes that progress is achieved one step at a time.

To meet increasing demand for greenhouse gas reduction, companies are looking to adopt climate-friendly hydrogen as a flexible, infinitely renewable energy source.

Get your Accelerating the Transition to Hydrogen Fuel e-book detailing the solutions to key challenges OEM's face in hydrogen processes. In this e-book, you will learn about:

Complete the form to access your complimentary copy of our Accelerating the Transition to Hydrogen Fuel e-book today.