Environmental Sustainability

Emerson helps customers across some of the world’s most essential industries make measurable sustainability progress, and we stand poised to help others along the same journey.

The capture efficiency of the CO2 is dependent on the solvent circulation rate. The higher the circulation rate, the more energy required in the stripper reboiler. There is therefore a trade-off between the capture efficiency and the energy cost to regenerate the solvent.

PacMotion Variable Frequency Drive

Compact, simple, and built to meet the demands of many different industrial needs.

Meeting the target CO2 capture rate in the most efficient manner possible is the challenge. Monitoring the capture percentage with on-line analysis allows for process optimization through multivariable control and analytics.

DeltaV

Our easy and flexible automation systems eliminate operational complexity and minimize project risk.

Digital Twin

Enable operator training and advanced testing of equipment and processes through dynamic simulation.

PACEdge Core Software Installer

PACEdge provides all aspects of edge processing to simplify your IIoT application development, deployment, and administration.

Micro Motion Compact Density Meter

Corrosion and erosion are significant concerns in an amine unit. Carbonic acid attack is possible where water vapor condenses in the presence of CO2. Two phase flow at the feed to the stripper also results in erosion concerns. Sheer rates, turbulence and steam velocities are also key for corrosion and erosion control.

Reducing fugitive emissions and the risk of process leaks is also important for the amine treating unit.

Rosemount Wireless Permasense

Permasense non-intrusive systems use sensor technology and wireless data delivery to continuously monitor for metal loss.

Roxar™ Retractable Electrical Resistance (ER) Probes

An accurate and reliable tool to measure real time corrosion in common environments such as oil, gas and water to sustain pipeline and asset integrity.

Rosemount X-Well

Emerson’s temperature measurement products provide innovative solutions for your most challenging applications.

Fisher™ ENVIRO-SEAL™ Control Valve Packing Systems

Live-loaded packing systems offer exceptional stem sealing to protect the environment against the emission of hazardous or polluting fluids.

Heat stable salts can accumulate in the amine solvent. This can result in foaming, fouling, and emulsions that can all impede reliability, which in turn impacts throughput and treatment capacity. Make-up rates for the amine should be optimized to avoid these problems.

Also, the reliability of valves of all types have significant impact on the reliability, efficiency and safety of the amine treating unit.

DeltaV™ Predict and PredictPro

DeltaV Predict/Pro enables you to obtain greater throughput, reduced variability, and increased safety for your model predictive control strategies.

Anderson Greenwood Series 200/400/500/700/800 Pilot Operated Relief Valves

Premium performance and advanced technology for overpressure protection

Control Valve Outgassing Sizing Tool

In outgassing applications, specialized control valve sizing and selection practices are needed to ensure capacity needs, vibration risk, and erosion concerns are addressed.

KTM Metal Seated Valve

The world’s first supplier of full-bore, split-body ball valves and pioneered soft- and metal-seated valves.

Bettis RTS actuator

RTS fail-safe electric actuators are designed and field proven for precise process control and reliable shutdowns.

Fully leverage engineering expertise and solutions to lower carbon emissions.

Emerson’s advantage lies in our innovative technological capabilities. In emerging markets, modern technologies can be the difference between short-term and long-term success.

Emerson’s deep, global expertise in technologies and services can help any industry take on the tough challenge of adopting carbon capture at scale while reducing risk.

Emerson has solutions for the carbon capture process, giving our customers the competitive edge of working with a partner with deep domain expertise to address a variety of application challenges.

Frequently Asked Questions about the Carbon Capture Process

Carbon capture has the potential to play a key role in reducing emissions from the hardest-to-abate industry sectors, particularly cement, steel and chemicals. For some industrial and fuel transformation processes, carbon capture is one of the most cost-effective solutions available for large-scale greenhouse gas (GHG) emissions reductions – especially those that inherently produce a relatively pure CO2 stream.

The carbon capture process separates CO2 from liquids or gases, usually hydrocarbon-based fossil fuels, combustion emissions, or ambient air from the atmosphere, by means of chemical reactions. The process of capturing carbon has been used for decades to remove CO2 from natural gas to improve purity. Since the 1970s, captured CO2 has been piped to oil fields and utilized to enhance oil recovery. In more recent times, capture technology has been successfully coupled with underground injection and sequestration of CO2.

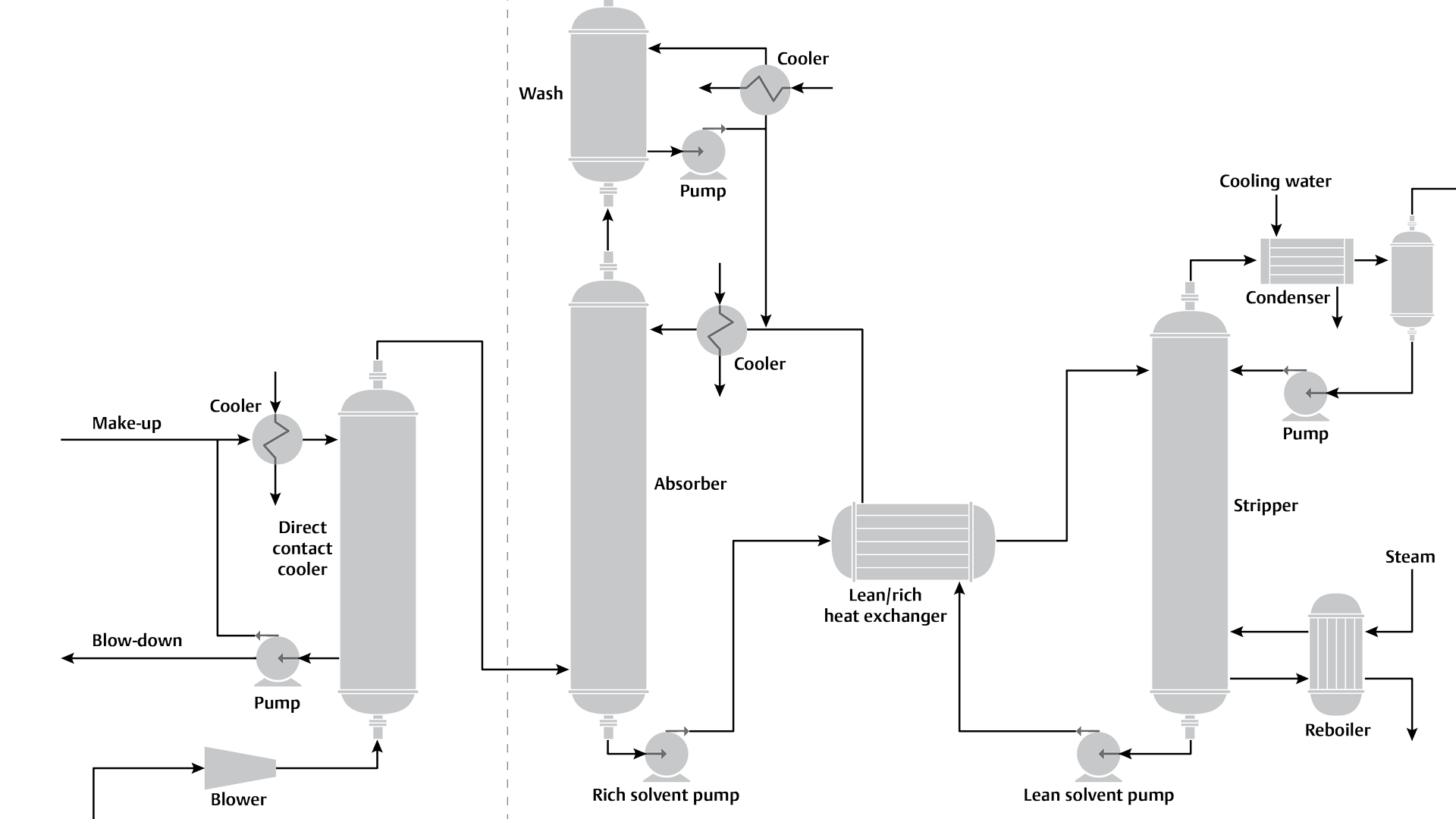

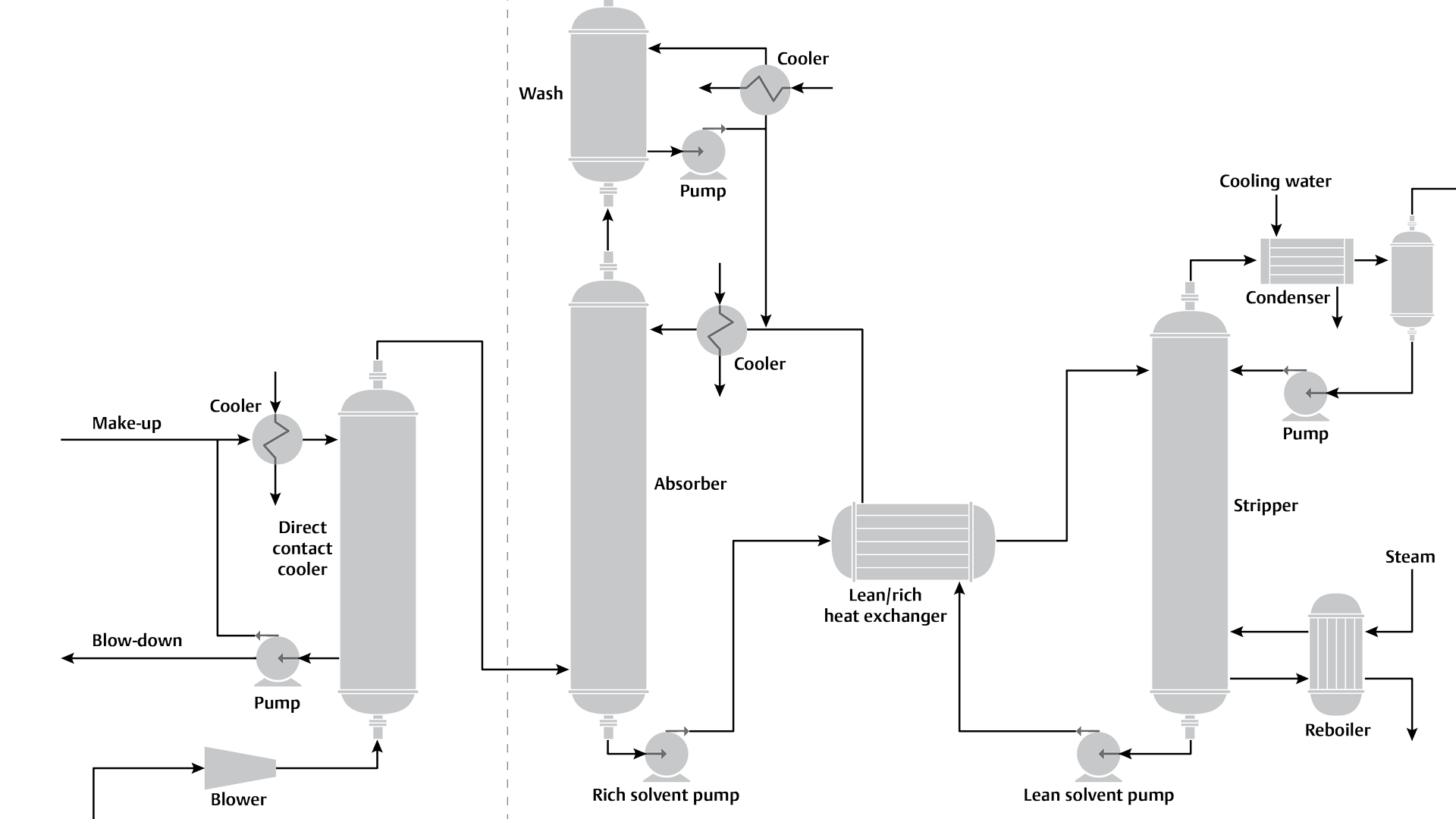

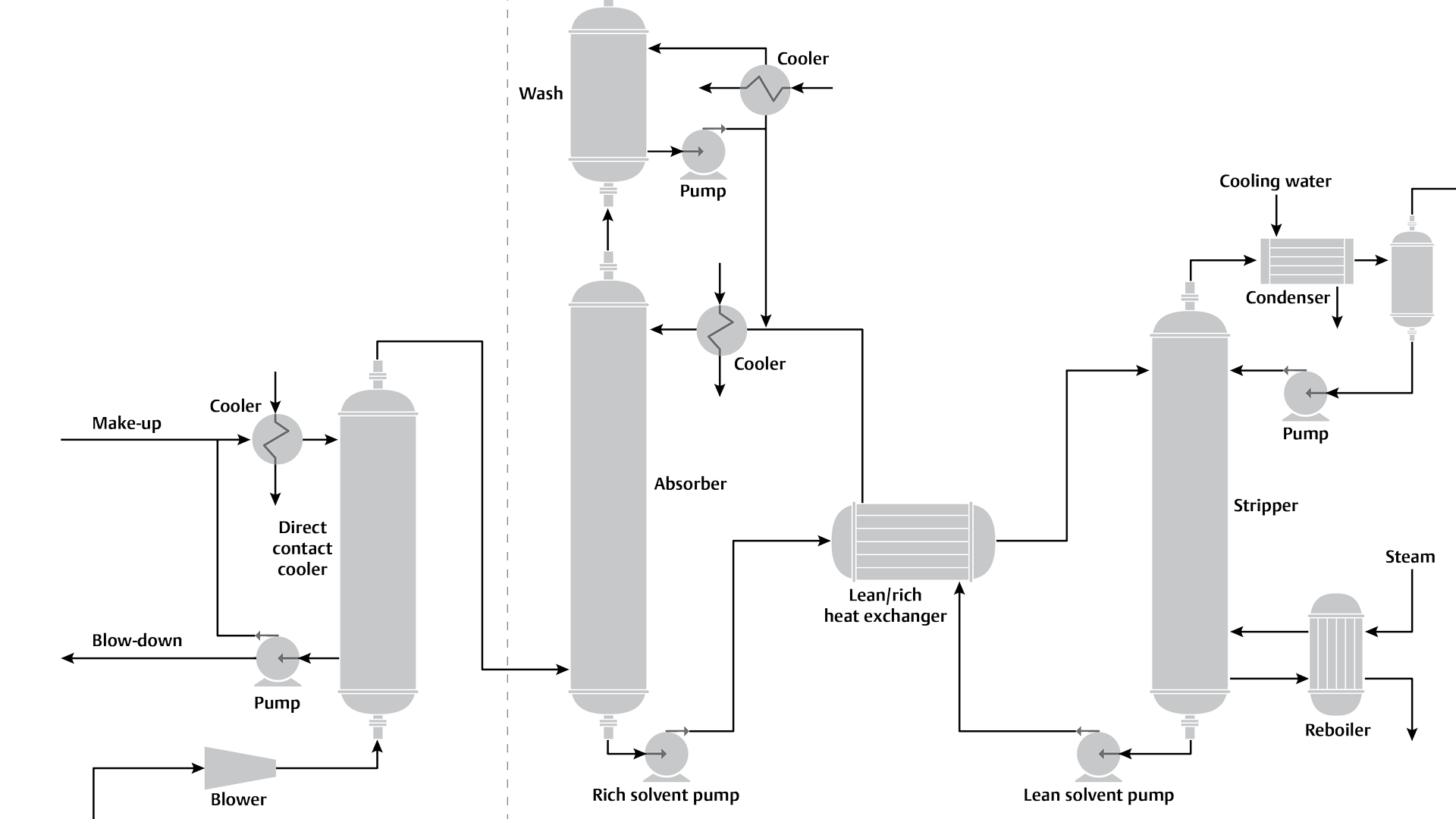

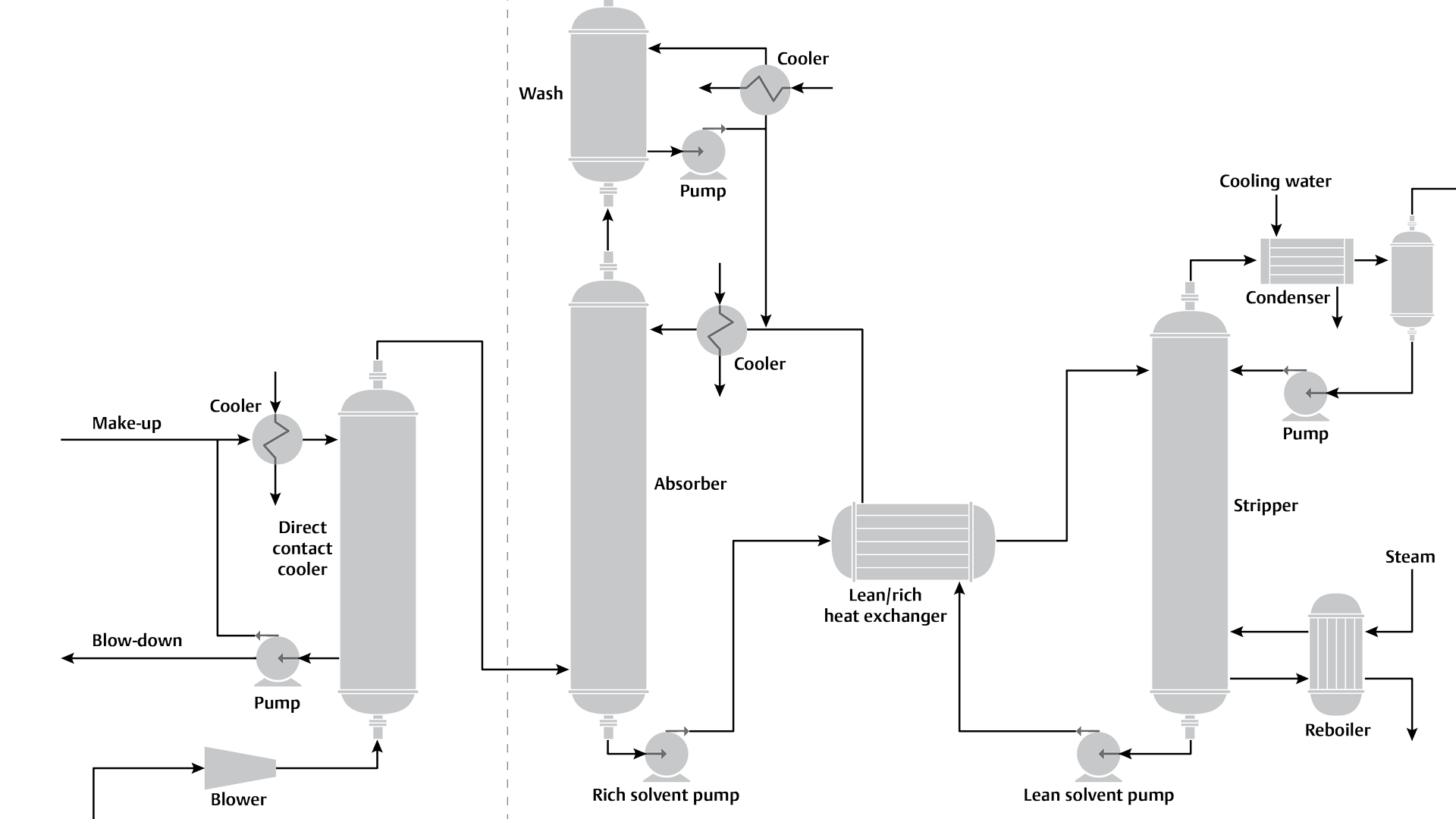

The most mature method of capturing carbon is post-combustion amine-based absorption. It consists of an absorber, where a chemical solvent captures CO2 from the flue gas, and a stripper where the chemical solvent is regenerated, and the CO2 is extracted. CO2 capture efficiency is dependent on the solvent circulation rate. Increasing the circulation rate increases the energy required for the stripper reboiler, which creates a trade-off between the capture efficiency and energy cost to regenerate the solvent. The goal is to continuously meet the target CO2 capture rate in the most efficient way possible.

Automation can solve the challenges involved with carbon capture in four key areas: energy intensity, process efficiency, corrosion and erosion, and safety and reliability. Advanced process control systems with multivariable analytics software enable capture rate optimization, while energy management information systems (EMIS) designed to detect poor performance can reduce site energy usage by up to 15%. Coriolis density meters automate amine concentration measurement to determine solvent circulation rate, making it easier to achieve the desired level of capture efficiency at the lowest cost. Non-invasive temperature sensors, corrosion detection systems, and online machinery health monitoring all reduce downtime, and pressure safety valves offer greater stability and tightness, reducing leakages and preventing containment losses.

“Carbon capture is a key initiative in reaching carbon neutrality. Without massive investment in carbon capture, we won’t succeed. On the other end, carbon capture is still very CAPEX and OPEX-intensive. So everything we can do to optimize the process so it’s commercially balanced--ease with R&D, industrial scale-up--are critical success factors.”

Aurelien Tissot

Director of Europe Marketing, Sustainability Engagement Leader